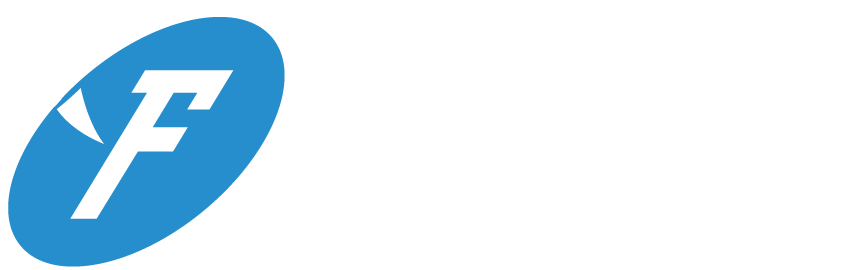

MRU 8000-LP Series Optimization Skid – For Electric- and Engine-Driven Compressors

The Maximizer™ 8000-LP Series Gas Lift Compression Optimization Skid is proven to reduce compressor shutdown events and increase uptime for both engine-driven and electric-driven gas lift compression systems. Manufactured in a controlled environment and not built on-site, the Maximizer™ 8000-LP can significantly cut facility construction time while improving overall system reliability and uptime. A patented* system, the 8000-LP Series also reduces methane emissions from gas lift operations by as much as 100%, targeting sources as low as ounces of PSI.

To best meet the customer’s unique operating requirements, the 8000 Series can be configured in two ways – without an inlet separator (MRU 8000-LP) and with an inlet separator (MRU 8000-LP IS).

Both the MRU 8000-LP and the MRU 8000-LP IS are available for lease or purchase with an associated service agreement on the MRU Control Skid-LP.

*US Patents 10519983, 11255349, 11,466,703

MRU Control Skid-LP and MRU 8000-LP IS

For applications with an existing inlet separator installed, a Maximizer™ MRU 8000-LP Series can be configured with Methane Recovery Control Skid (Maximizer™ MRU Control Skid-LP) and Maximizer™ MRU 8000-LP. This combination MRU Control Skid-LP and MRU 8000-LP provides a number of benefits.

- Up to 100% reduction in methane emissions

- NGL liquid processing from sources at any psi

- Methane capture capability from sources at any psi, including reciprocating compressor packing vents and blowdowns

- Compressor facility liquid level shutdown prevention

- Elimination of methanol injection to prevent reciprocating compressor liquid level freeze-up

- Instrument supply header designed to utilize gas or instrument air

This system also includes:

- Monthly Methane Capture reporting for any psi

- Initial facility survey and compressor reliability recommendations*

- 2 hours/month compression facility reliability consultation*

- Full maintenance and repair of the system*

- Methane capture measurement

- Quarterly methane capture meter calibration

- Telemetry system to identify a leaking or stuck dump valve event

- Fuel gas consumption measurement and reporting for engine-driven reciprocating compressors

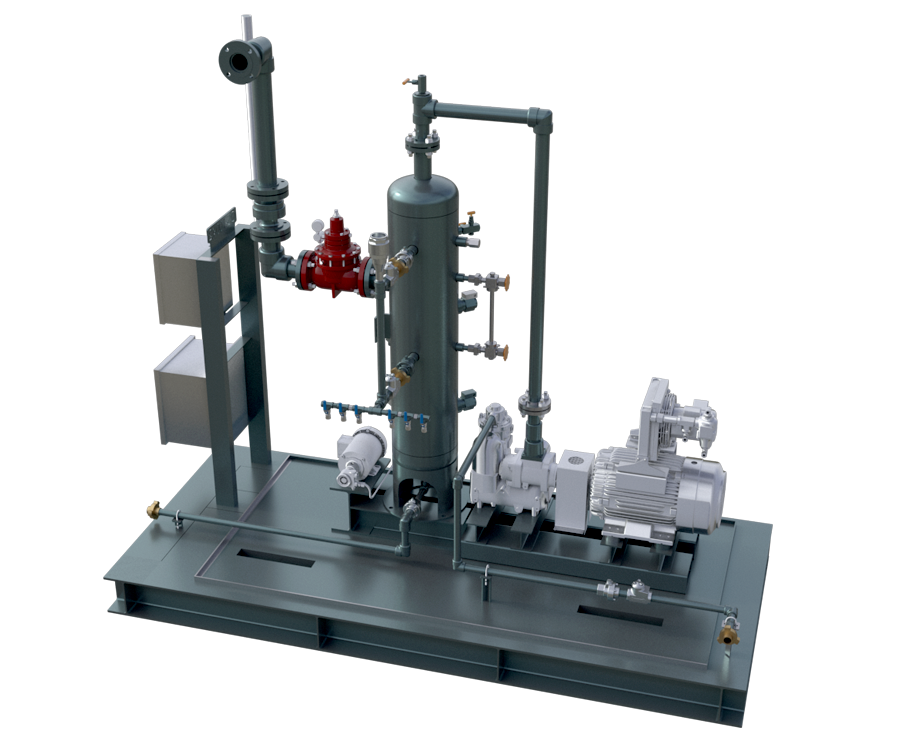

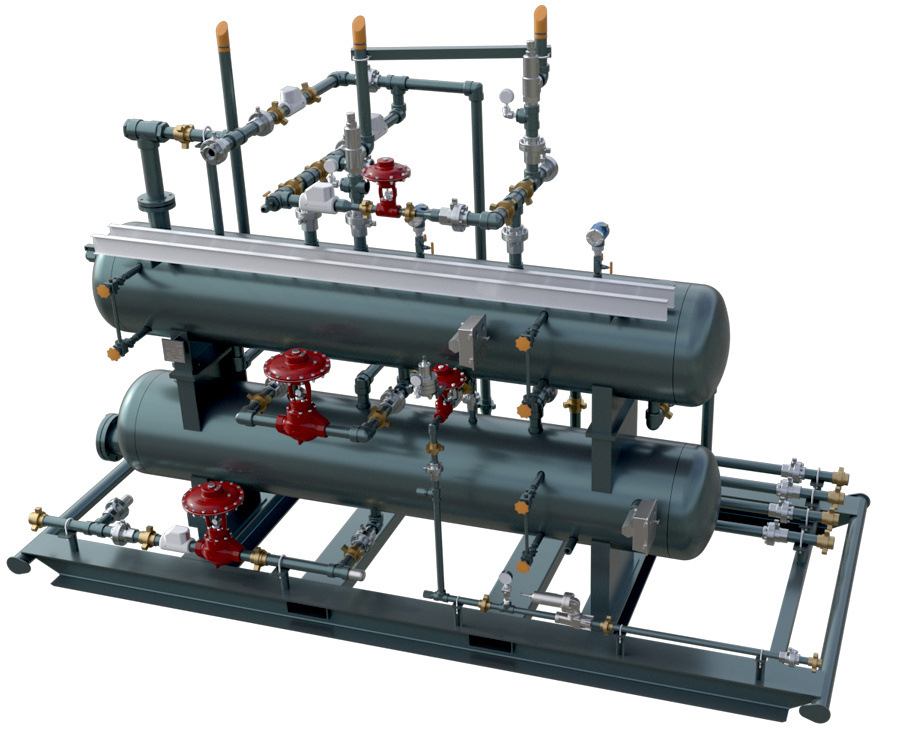

MRU Control Skid-LP and MRU 8000-LP IS

The Maximizer™ MRU 8000-LP IS is designed for use in gas lift facilities, electric- or engine driven, where there is not an existing inlet separator installed. The IS system includes the Methane Recovery Control Skid-LP (Maximizer™ MRU Control Skid-LP) and Maximizer MRU 8000-LP IS. This combination MRU Control Skid-LP and MRU 8000-LP IS provides a number of key benefits.

- Fully integrated gas compression optimization package with inlet separator included

- Up to 100% reduction in methane emissions

- NGL liquid processing from sources at any psi

- Methane capture capability from sources at any psi, including reciprocating compressor packing vents and blowdowns

- Compressor facility liquid level shutdown prevention

- Elimination of methanol injection to prevent reciprocating compressor liquid level freeze-up

- Instrument supply header designed to utilize gas or instrument air

- Can be used with electric- or engine-drive compressors

This system also includes:

- Monthly Methane Capture reporting for any psi

- Initial facility survey and compressor reliability recommendations*

- 2 hours/month compression facility reliability consultation*

- Full maintenance and repair of the system*

- Methane capture measurement

- Quarterly methane capture meter calibration

- Telemetry system to identify a leaking or stuck dump valve event

- Fuel gas consumption measurement and reporting for engine-driven reciprocating compressors